BLW MANUFACTURE INTERNATIONAL CO.,LTD.

BLW Silicon coating fabric

What is silicone?

Silicone is an inert synthetic compound that come in a variety of forms (oil, rubber, resin). Typically, heat-resistant and rubber-like, they are present in sealants, adhesives, lubricants, medical applications, cookware and insulation. Silicone is a polymer that contains silicon, combined with carbon, hydrogen and oxygen and, in some cases, other elements.

The basic structure of silicone is made up of polyorganosiloxanes, where silicon atoms are linked to oxygen to create the «siloxane» bond. The remaining valences of silicon are linked to organic groups, mainly methyl groups (CH3): Phenyl, vinyl or hydrogen.

How silicone is made?

The key is to create chlorosilanes, which are compounds prepared by combining silicon powder and methyl chloride gas through direct synthesis by means of an electrochemical process. The resulting methyl chlorosilanes (trimethyl, dimethyl and methyl chlorosilane) are the building blocks for various silicone substances.

Silicone Properties

Silicone, due to its polysiloxane, provide several advantages:

Silicones, the sustainable solution for high performance coated fabric

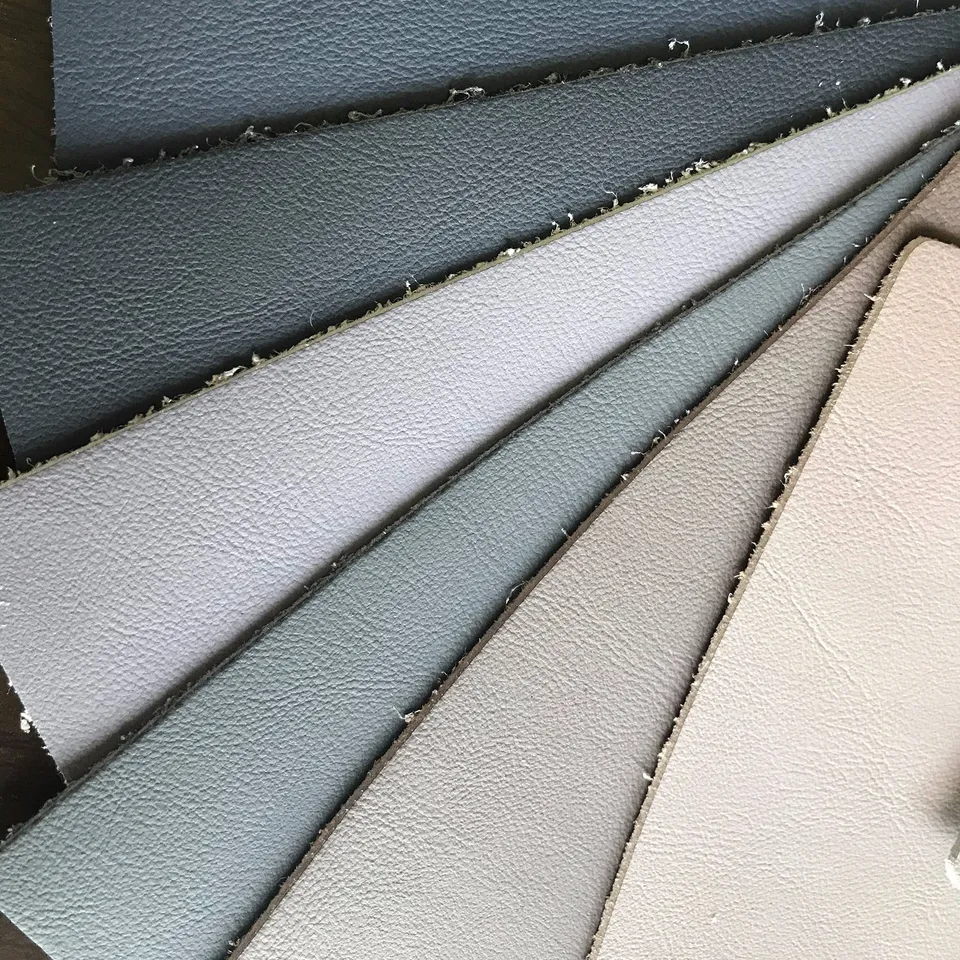

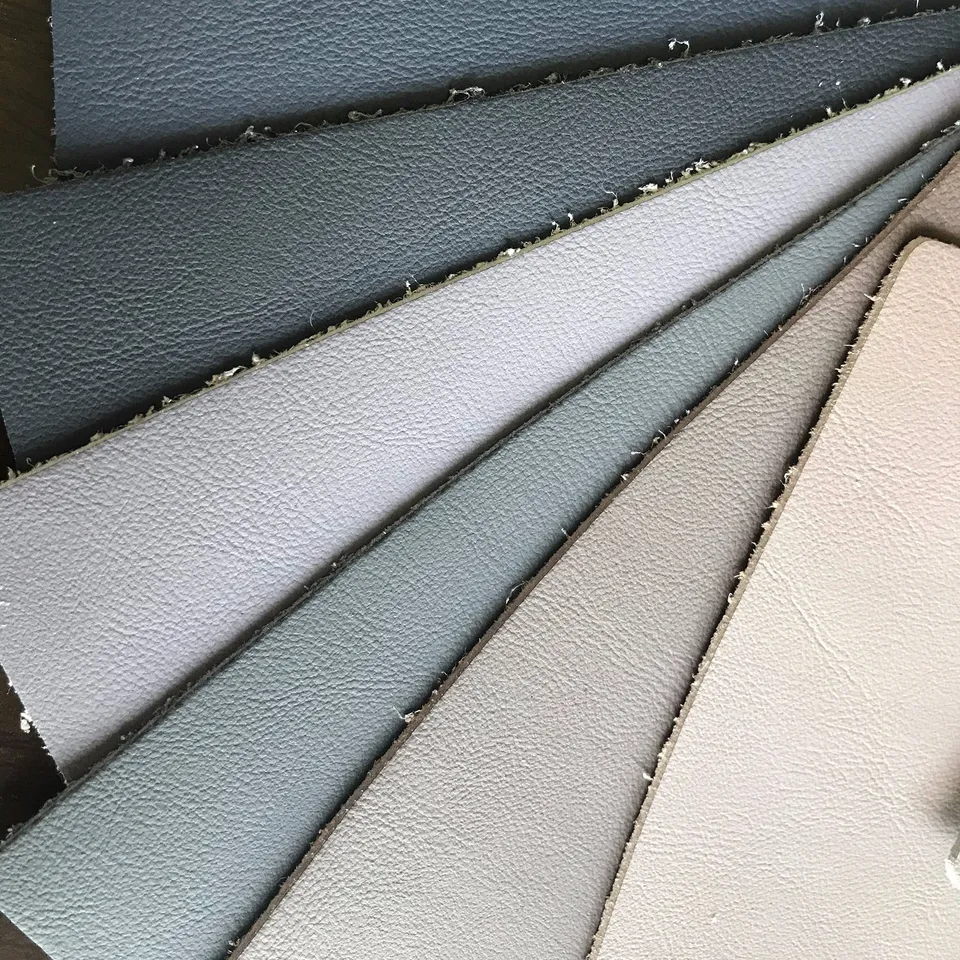

Are you limited by the selection of authentic leather or polyurethane coated textiles? Silicone chemistry is disrupting the world of coated textiles with a performance fabric that looks and feels like leather but is totally different.

Polyurethane and PVC coated fabrics are no longer your only option when looking for sustainable coated textiles or leather alternatives. Silicone elastomers are extremely durable, offer a modern look and comfortable feel while remaining free of solvents, offering an eco-friendly solution.

BLW Textile Coating Silicones are used to create performance fabrics for high-end products such as outdoor furniture, automotive interiors, medical equipment, and sporting goods.

Silicone polymers and elastomers are ideal for these applications due to their renowned ability to withstand the harshest conditions while still being soft and flexible. Silicone elastomeric coatings are also skin friendly, contain no phthalates, solvents, or harmful chemicals. Since silicones are easy to handle, processes can be optimized to reduce total material and/or energy usage.Thermal stability (from -80°C to 250°C)

Resistance to natural ageing (oxidation, UV)

Resistance to fire, low emission of smoke and toxic fumes, self-protection, ceramization of ashes

Low surface energy

Good wetting on many substrates

Hydrophobia (beading effect)

Release or adhesion properties, according to need

Exceptional harmlessness for a wide range of applications

Biocompatibility, well-suited for food contact and medical applications

Safe and comfortable skin contact

Flexible chain of up to -100°C for enhanced lubrication and gas permeability performance

Easy processing, excellent spread and coating capabilities

Available in a variety of forms - fluids, liquid silicone elastomers (LSR) and high-consistency rubbers (HCR)

Functional advantages of Silicones:

Environment-friendly

Solventless

UV and aging resistance

Heat and fire resistance

Flexibility remains at high and low temperatures

Good abrasion resistance

Durable adhesion to variety of substrates

An ideal material to be associated with coated textiles, silicone elastomers enable the creation of composites comprised of multiple layers each bringing unique properties essential to the performance feel and look on top of your chosen substrate. Depending on your targeted end use the specific TCS products are carefully chosen and assembled to deliver perfect performance.

Incorporating silicone coated textiles into your design is also about making an eco-responsible choice. Silicones are a durable alternative to conventional plastics that preserves our environment. From water to UV resistance, protecting against heat and fire, eco-friendly, silicones are changing the way you see and create high performance coated textiles.

-

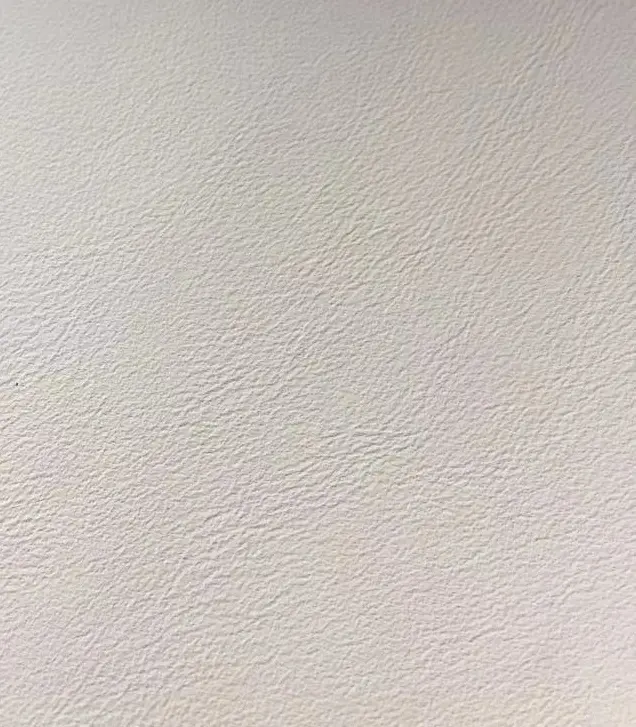

BLW723 Silicone Waterproof Anti Bacterial Easy Clean Environmentally Friendly Inorganic Eco Friendly Sofa Leather

Decorative, Chair, Furniture, Sofa, Notebook, Bedding, BABY & KIDS, Bags,Purses & Totes, Coat and Jacket, Costumes, Sleepwear¥ 0.00Comprar ahora

-

FU1811 Microfiber Car Seats Cars Automotive Faux Synthetic Leather

Car Seat, Car, Upholstery¥ 0.00Comprar ahora

-

BLW738 MICROFIBER LEATHER ARTIFICIAL LEATHER FURNITURE SOFA AUTOMOTIVE CAR SEAT STOCK GOODS

Home Textile, Decorative, Furniture, Sofa, Car Seat, Upholstery, project, office furniture, etc.¥ 0.00Comprar ahora

-

BLW533 SA6083 EMBOSSED MICROFIBER LEATHER ARTIFICIAL LEATHER LONG HAIR BACKING FURNITURE SOFA AUTOMOTIVE CAR SEAT STOCK GOODS

Home Textile, Decorative, Furniture, Sofa, Car Seat, Upholstery, project, office furniture, etc.¥ 0.00Comprar ahora

-

BLW533 SA6081 HIGH ABRASION RESISTANCE MICROFIBER LEATHER PLAIN DESIGN FURNITURE SOFA AUTOMOTIVE CAR SEAT STOCK GOODS

Home Textile, Decorative, Furniture, Sofa, Car Seat, Upholstery, project, office furniture, etc.¥ 0.00Comprar ahora

-

BLW682 Waterproof Customized Colors Embossed Leather Car Interior Car Seat Sofa Shoes Microfiber Leather

Home Textile, Decorative, Chair, Bag, Sofa, Car Seat, Car, Shoes, Upholstery¥ 0.00Comprar ahora

-

FB1077 100 Polyester Cotton Fabric Home Textile Sofa Furniture Office Chair Car Seat Cover

Car, Bag, Bedding, Lining, Mattress, Tent, Curtain, Dress, Garment, Home Textile, Sofa, Toy, Upholstery, Wedding, Luggage, BABY & KIDS, Coat and Jacket, Costumes, Home Decor¥ 0.00Comprar ahora

-

No.BLW691-3 100 Polyester Textile Fabric Sofa Chair Seat Home Furniture Office Car Cover

Bag, Bedding, Mattress, Curtain, Garment, Home Textile, Shoes, Sofa, Upholstery, Wedding, Luggage, Bags,Purses & Totes, Coat and Jacket, Home Decor, Fashion Accessories-Luggage¥ 0.00Comprar ahora

-

BLW658 100% Poly Customized Color Patterns Fabrics Furniture Sofa Bag

Awning, Car, Felt, Bag, Bedding, Curtain, Dress, Home Textile, Sofa, Suit, Bags,Purses & Totes, Coat and Jacket, Costumes, PILLOWS¥ 0.00Comprar ahora

-

BLW679 Fabric Bags Shoes Soft Glitter Jacket Notebook Waterproof Baby Coat Kids Entry Lux High-end Fabrics

Bag, Bedding, Curtain, Shoes, Sofa, Coat and Jacket, PILLOWS¥ 0.00Comprar ahora

Quick Navigation