BLW MANUFACTURE INTERNATIONAL CO.,LTD.

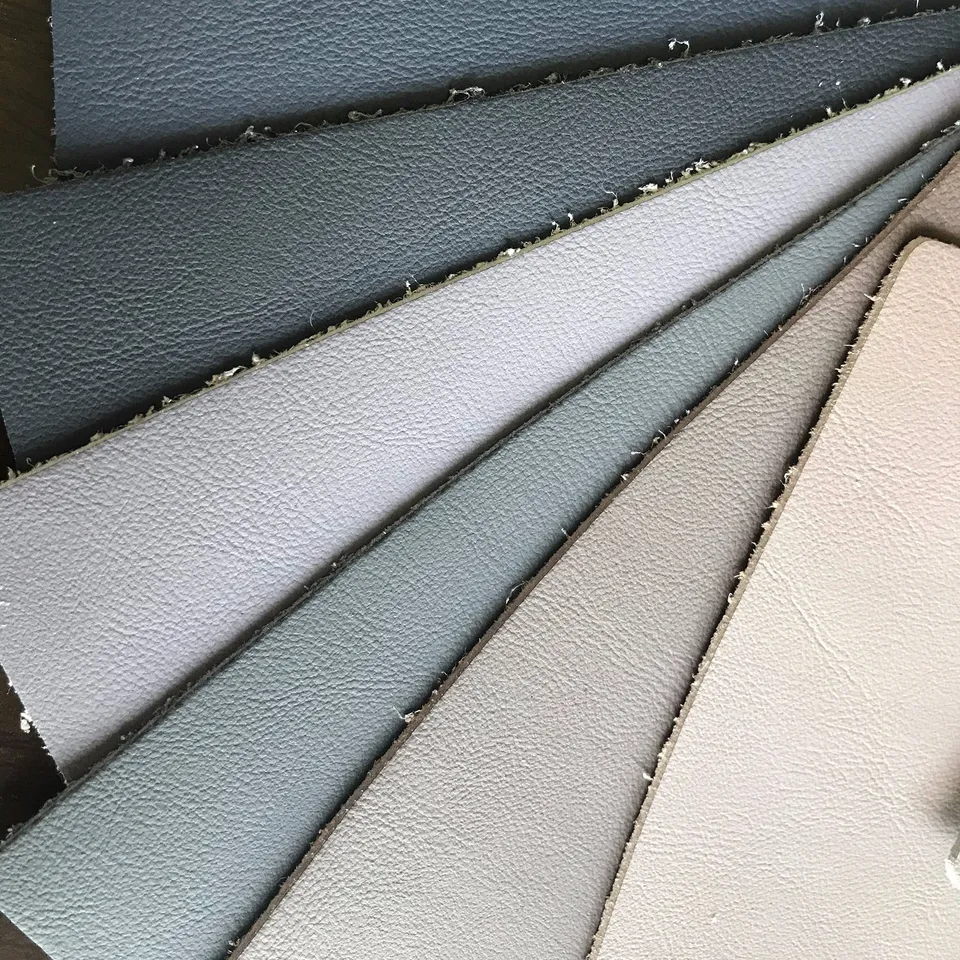

BLW Solvent free PU

At present, we mainly use solvent based adhesives for leather, polyurethane and food flexible packaging composite films production. The residual amount and migration of solvents have always troubled the health and safety of the leather industry and food packaging. The harmful impact of solvent emissions on the environment is harmful to people's health.

The solvent-free composite technology completely meets the requirements of high efficiency, environmental protection and energy conservation. Its process flow is simple, energy consumption is low, raw materials are saved, and the speed of production is high. There is no solvent residue in the production process, which will not cause harm to human body or the environment. Solvent free adhesive is coated without solvent, which is not limited by solvent emissions and meets the national requirements for environmental protection.

Performance

Solvent free PU has strong temperature adaptability, can be cured even at - 40 ℃.

High Abrasion resistance, can reach Martindale abrasion resistance 200,000 times.

Peeling resistance

Corrosion resistance and oxidation resistance

Fire Retardent

Anti-bacterial and mildewproof

Hydrolysis resistance, Long service life, low odor

Soft hand feeling, high resilience and high toughness

easy clean

Environmental friendly

It does not contain any solvent or volatile organic compounds, nor toxic and harmful substances such as amine, coal tar, isocyanate monomer. It does not contain combustibles, not pollute the environment, and conforms to industrial safety.

Formaldehyde Free

DMF Free

AZO Free

Mildew Resistant

non-toxic

Odor free

ROHS

REACH

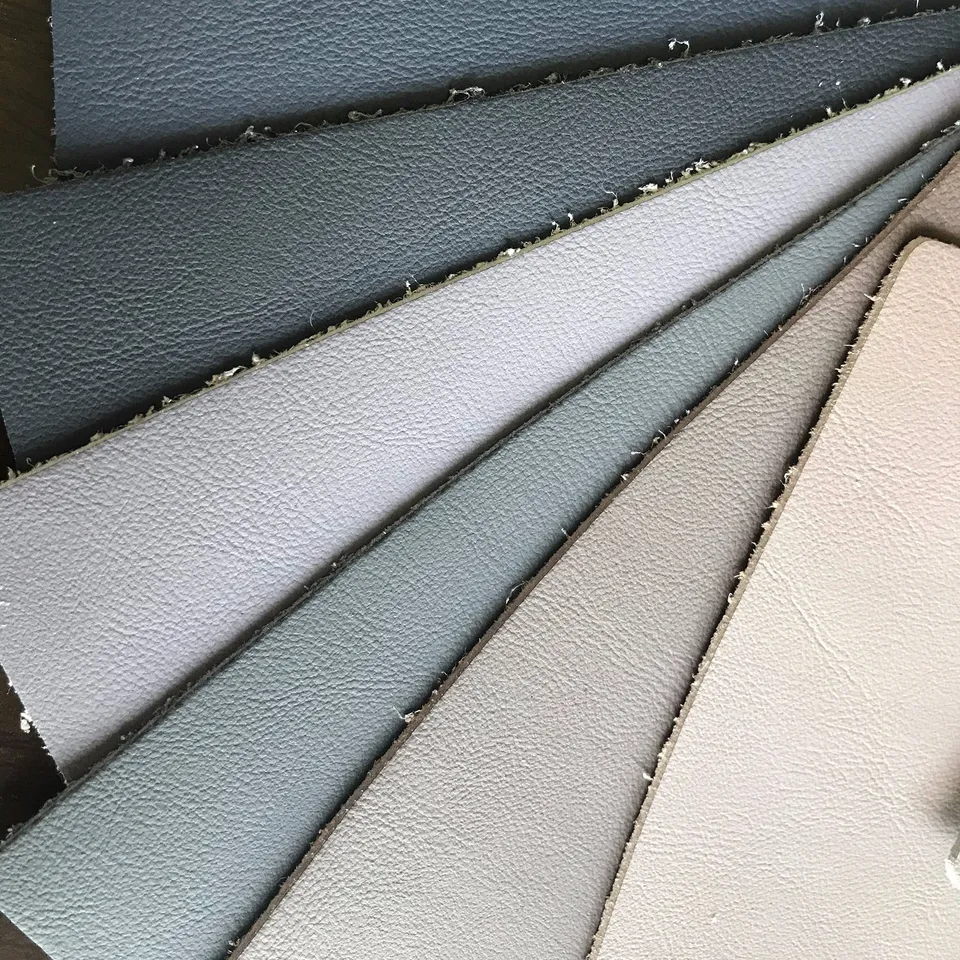

Widely used in different industries

Suitable for furniture, shoes, bags, packaging, clothes, etc.

-

BLW723 Silicone Waterproof Anti Bacterial Easy Clean Environmentally Friendly Inorganic Eco Friendly Sofa Leather

Decorative, Chair, Furniture, Sofa, Notebook, Bedding, BABY & KIDS, Bags,Purses & Totes, Coat and Jacket, Costumes, Sleepwear¥ 0.00Comprar ahora

-

FU1811 Microfiber Car Seats Cars Automotive Faux Synthetic Leather

Car Seat, Car, Upholstery¥ 0.00Comprar ahora

-

BLW738 MICROFIBER LEATHER ARTIFICIAL LEATHER FURNITURE SOFA AUTOMOTIVE CAR SEAT STOCK GOODS

Home Textile, Decorative, Furniture, Sofa, Car Seat, Upholstery, project, office furniture, etc.¥ 0.00Comprar ahora

-

BLW533 SA6083 EMBOSSED MICROFIBER LEATHER ARTIFICIAL LEATHER LONG HAIR BACKING FURNITURE SOFA AUTOMOTIVE CAR SEAT STOCK GOODS

Home Textile, Decorative, Furniture, Sofa, Car Seat, Upholstery, project, office furniture, etc.¥ 0.00Comprar ahora

-

BLW533 SA6081 HIGH ABRASION RESISTANCE MICROFIBER LEATHER PLAIN DESIGN FURNITURE SOFA AUTOMOTIVE CAR SEAT STOCK GOODS

Home Textile, Decorative, Furniture, Sofa, Car Seat, Upholstery, project, office furniture, etc.¥ 0.00Comprar ahora

-

BLW682 Waterproof Customized Colors Embossed Leather Car Interior Car Seat Sofa Shoes Microfiber Leather

Home Textile, Decorative, Chair, Bag, Sofa, Car Seat, Car, Shoes, Upholstery¥ 0.00Comprar ahora

-

FB1077 100 Polyester Cotton Fabric Home Textile Sofa Furniture Office Chair Car Seat Cover

Car, Bag, Bedding, Lining, Mattress, Tent, Curtain, Dress, Garment, Home Textile, Sofa, Toy, Upholstery, Wedding, Luggage, BABY & KIDS, Coat and Jacket, Costumes, Home Decor¥ 0.00Comprar ahora

-

No.BLW691-3 100 Polyester Textile Fabric Sofa Chair Seat Home Furniture Office Car Cover

Bag, Bedding, Mattress, Curtain, Garment, Home Textile, Shoes, Sofa, Upholstery, Wedding, Luggage, Bags,Purses & Totes, Coat and Jacket, Home Decor, Fashion Accessories-Luggage¥ 0.00Comprar ahora

-

BLW658 100% Poly Customized Color Patterns Fabrics Furniture Sofa Bag

Awning, Car, Felt, Bag, Bedding, Curtain, Dress, Home Textile, Sofa, Suit, Bags,Purses & Totes, Coat and Jacket, Costumes, PILLOWS¥ 0.00Comprar ahora

-

BLW679 Fabric Bags Shoes Soft Glitter Jacket Notebook Waterproof Baby Coat Kids Entry Lux High-end Fabrics

Bag, Bedding, Curtain, Shoes, Sofa, Coat and Jacket, PILLOWS¥ 0.00Comprar ahora

Quick Navigation